ARMOR'S SHEETING & SEALANT PACKAGE

MATERIALS

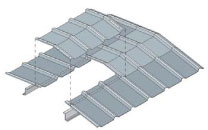

There are four factors that make the strength of the Armor roof and wall panels one of the highest in the industry; the 80,000 PSI hi-tensile strength, the 26 gauge minimal thickness (Available in 24 gauge also), the 42 inch wide coils that allow for a (36" net) wide sheet with 11/4" deep corrugations that act as a rigid steel stud and are 12 inches on center. The wider coil also allows for the purlin bearing rib (PBR) on both the roof and wall panels which supports the panels while being fastened at the overlaps and prevents oil-canning, spreading and leaking. Our semi-concealed wall panels are a very attractive option that is available on some models for a minimal charge.  COMPETITION: Many competitors use 50,000 PSI, 29-26 gauge panels that are only 38-41 inches wide which may allow as low as only a ¾ inch deep corrugation. This soft tensile strength, thinner, shallow corrugation and narrow material while cheaper allows for a much weaker panel and does not provide the PBR panel on both the walls and roof. These low quality factors allow the holes around the fasteners to become enlarged due to vibration and "humming" when the panels are put under pressure from wind and snow and may eventually cause leaking or in severe weather may cause the panel to fail which allows the entire building to twist and strips the panel from the building like peeling a banana. MASTIC ROOF SEALANTWe provide a 7/8" mastic tape for a double row, or bead, where the sheets overlap vertically at the ends of panels; such as at the ridge caps or on buildings that have overlaps on continuous slopes greater than 40 feet. We also provide the 7/8" mastic on the horizontal side of the panels where they overlap on the roof. This extra wide mastic assures a much tighter seal on the overlaps so that the fasteners, when penetrating the mastic and panels, will seal the screw and the penetration to assure no leaks when installed properly.  COMPETITION: Many competitors provide only 3/8" mastic and do not provide for the vertical double row at the end laps. This much narrower mastic is extremely difficult to place exactly in the center of the 1-1/4" wide overlap on the horizontal side laps of the panels. Therefore when the fasteners penetrate the panels it misses the mastic which allows for air pockets and leaks. Some brokers provide tubes of caulking which is also extremely messy and difficult to install or do not provide the mastic at all. RIDGE CAPSThe ridge cap is made of the same tensile strength, thickness, corrugation, and materials as the roof and wall panels and is roll-formed by the same precise equipment. It matches the corrugations in the roof panels and is then die-formed for the appropriate roof pitch to seal the peaks of the building where the two roof panels join. It is one of the other critical pieces to the roof system and is a 3'x3' piece that overlaps 6" at each vertical end lap again with a double row of 7/8" mastic. COMPETITION: Many competitors provide a flat sheet 24" x 24" ridge cap that requires hand bending and screws to the hi-ribs of the roof panel and does not match the corrugation. This allows air to flow under the ridge cap between the hi-ribs of the roof panel. Even though they may provide a closure in an attempt to seal the ridge it quickly deteriorates due to weather elements and birds trying to nest. Be careful of the competitors who tell you that the building comes with ridge vents standard. It does.

|